- 133C, H. P. Bunk Thottam,

Coimbatore - 641047 - +91 9744617454

info@blackbearautomations.com

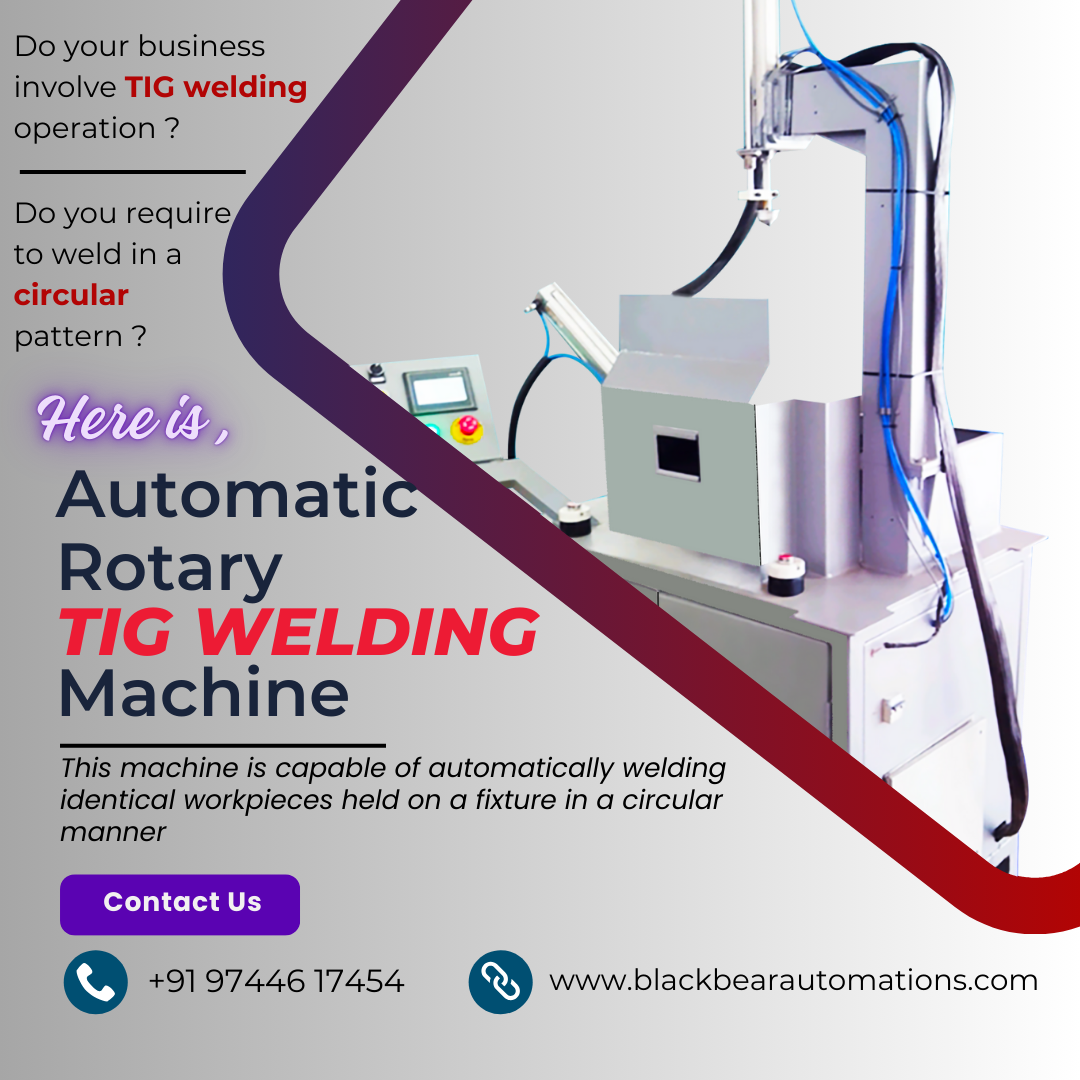

The Rotary TIG Welding Machine offers exceptional precision and efficiency for welding circular components. Ideal for aerospace, automotive, and manufacturing industries, it delivers high-quality welds with minimal spatter.

It features an advanced rotary mechanism and intuitive touchscreen controls, ensuring consistent and high-quality welds with minimal spatter. The machine supports various materials, including stainless steel and aluminum, and comes with essential safety features like overheat protection and emergency stop. Enhance your welding operations with the RT-2000, designed for optimal performance and user-friendly operation.

Overheat protection, gas flow sensors.

Meets all relevant industry standards

Industrial Welding Equipment.

The RT-2000 Rotary TIG Welding Machine is a high-precision, efficient solution designed for welding circular components in industries such as aerospace, automotive, and manufacturing. Featuring an advanced rotary mechanism, this machine ensures consistent, high-quality welds with minimal spatter. Its intuitive touchscreen controls make operation straightforward, while its versatility allows it to handle various materials, including stainless steel and aluminum. Equipped with essential safety features like overheat protection and an emergency stop, the RT-2000 is built for optimal performance and user safety, making it an excellent choice for enhancing welding operations.

The work scope of the RT-2000 Rotary TIG Welding Machine encompasses a variety of applications and tasks across multiple industries. Here are the key areas where this machine excels: