Manufacturing Services

At BlackBear, we are your trusted partner for cost-effective precision manufacturing services. With a commitment to quality, innovation, and cutting-edge technology, we offer a comprehensive range of manufacturing solutions to meet your unique needs.

Some of the services we provide include:

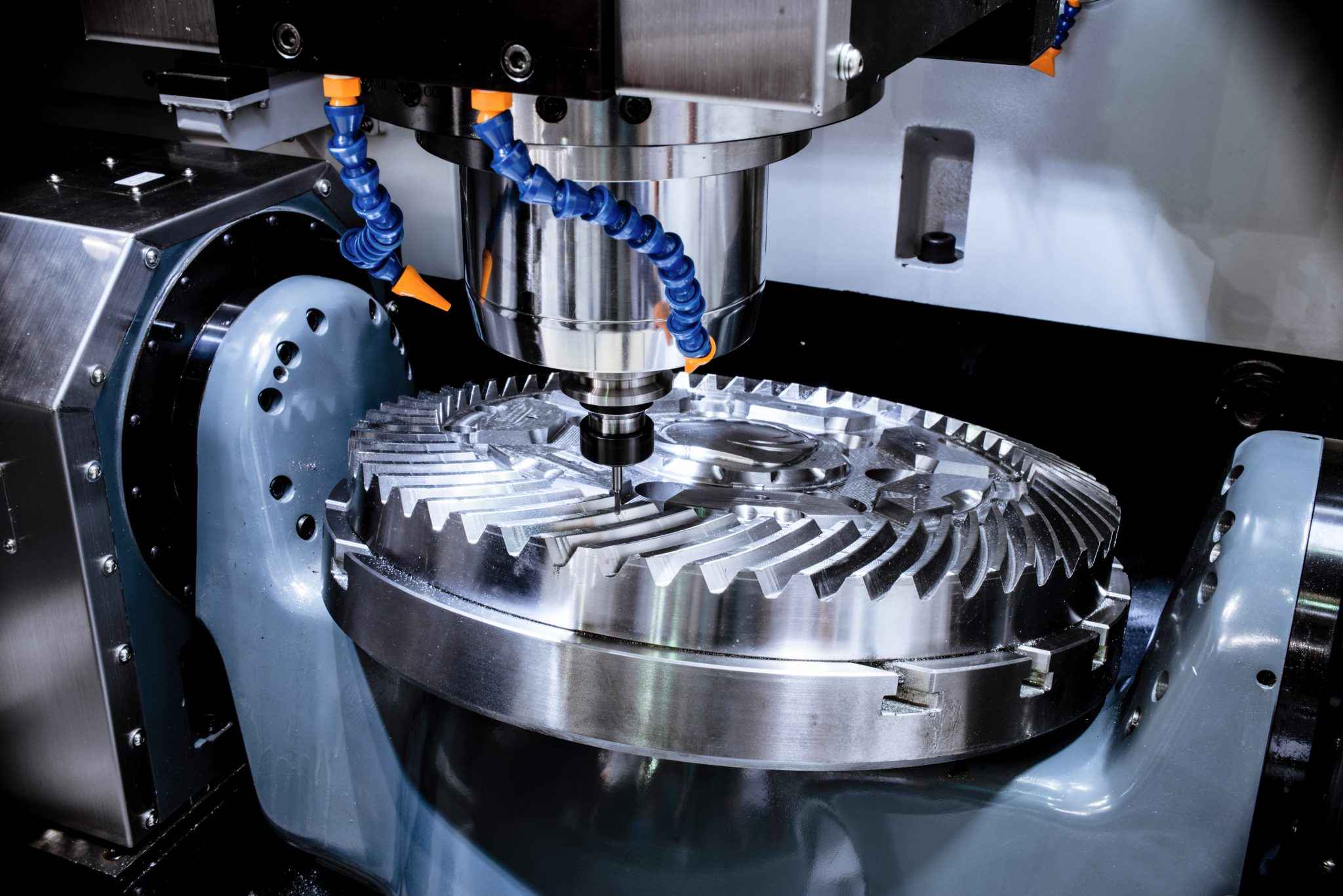

CNC Machining

As part of our manufacturing services portfolio, we offer high-precision CNC machining services tailored to meet the exacting needs of industries that demand quality, consistency, and speed. CNC machining enables the production of highly accurate, repeatable components with tight tolerances and complex geometries.

With a fleet of advanced CNC milling and turning centers, we deliver custom-machined parts to your specifications—on time, every time. We also offer value-added services including CAD/CAM design assistance, surface finishing (such as anodizing, plating, and powder coating), threading and tapping, part assembly, and comprehensive quality control.

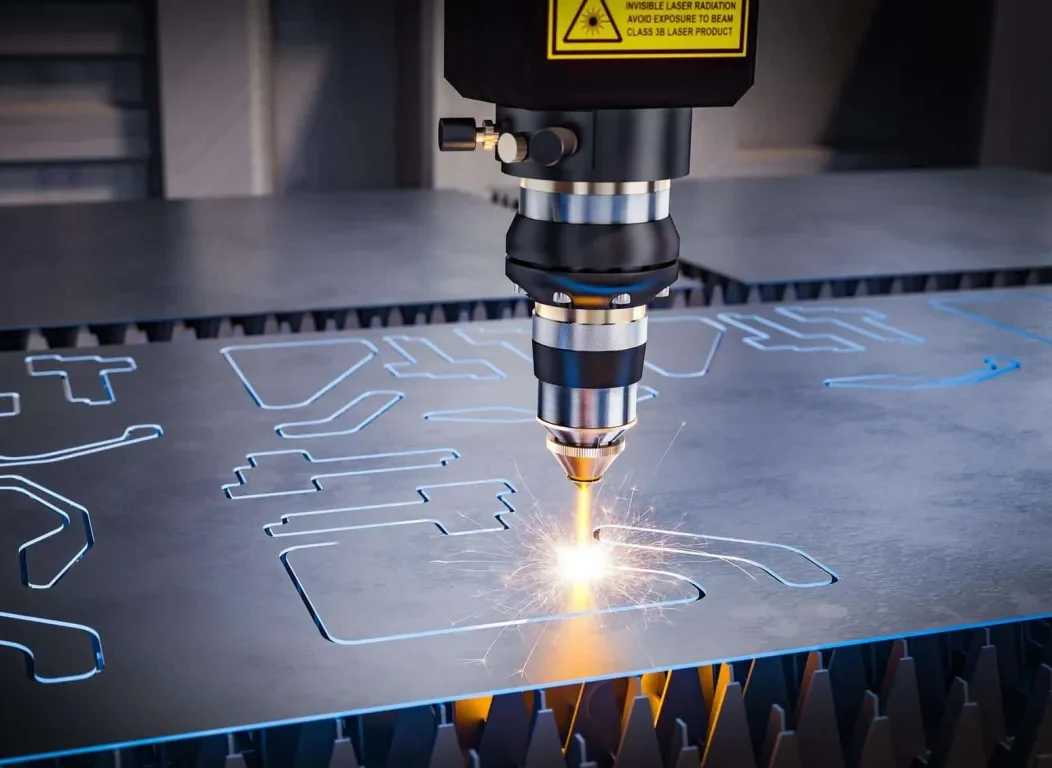

Laser Cutting

At Blackbear, we offer high-precision laser cutting services to meet the demands of today’s fast-paced manufacturing industries. Laser cutting ensures consistent quality, tight tolerances, and minimal material waste, making it ideal for complex designs and intricate patterns. With advanced laser systems, we deliver accurate, clean, and efficient cuts across a wide range of materials and thicknesses—whether for prototypes, custom parts, or full production runs.

We also offer material sourcing, CAD/CAM support, and finishing options for a complete end-to-end solution.

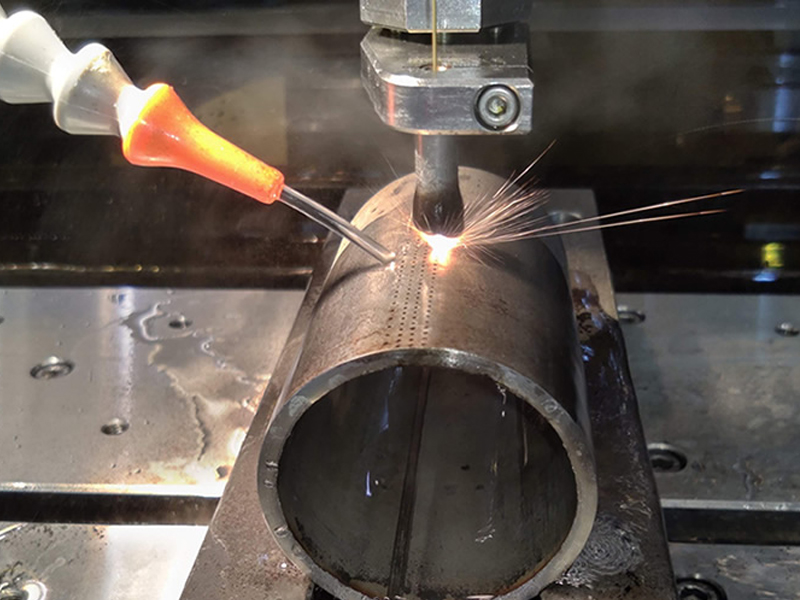

Laser Welding

We specialize in precision laser welding solutions for high-quality, high-strength metal joining applications. This non-contact method uses a concentrated laser beam and delivers deep, narrow welds with minimal heat distortion, making it perfect for thin materials, intricate assemblies, and components requiring a clean finish.

With a focus on quality, precision, and reliability, we deliver laser welding solutions tailored to your technical and production needs. Our team collaborates closely with clients to ensure each weld meets strict specifications, and our process is backed by rigorous inspection and quality assurance protocols.

CNC Bending

We offer precision CNC bending services as part of our advanced sheet metal fabrication capabilities. Our state-of-the-art CNC press brakes and skilled technicians ensure accurate and repeatable bends, no matter the complexity or volume of your project. Our services are backed by quality assurance and on-time delivery. Whether you’re working on a prototype or need full-scale production, we’re here to support your project every step of the way.

Injection Moulding

At Blackbear Automations, we deliver precision plastic parts using cutting-edge injection moulding technology. From large-scale production to custom small batches, we guarantee consistency, quality, and cost-efficiency for industries like automotive, medical, and consumer products.

We start with expert design and tooling to meet exact specifications. Using advanced machinery, we mould with precision, followed by finishing and assembly, ensuring production-ready parts every time. With a focus on accuracy and reliability, our in-house tooling assembly provide fast turnaround times, custom solutions, high-quality, durable materials.

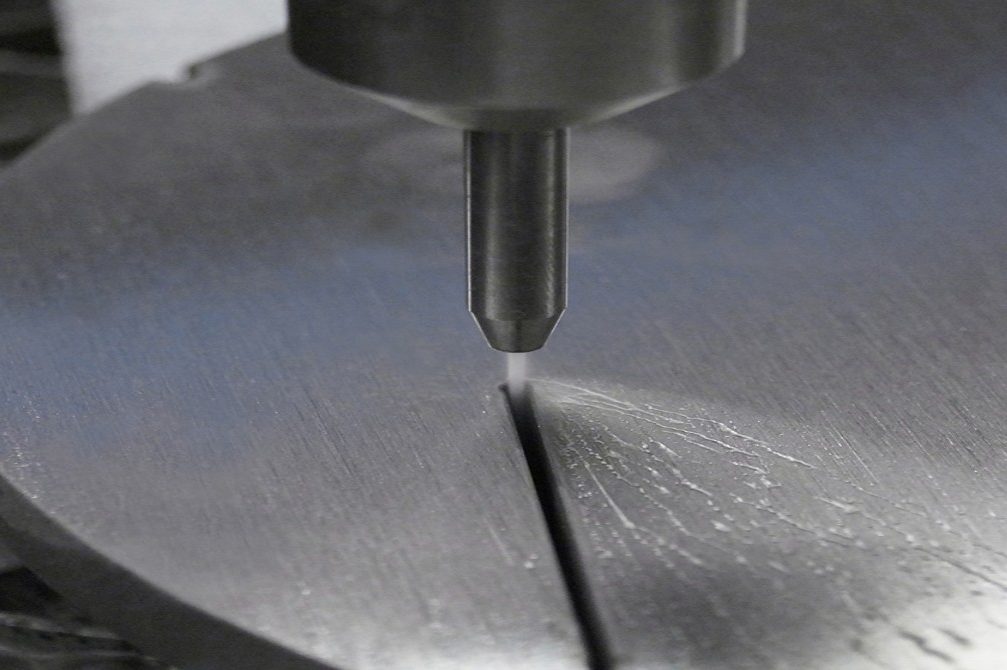

Waterjet Cutting

Our precision waterjet cutting services offer a fast, clean, and highly accurate method for cutting a wide range of materials without the use of heat. Using high-pressure streams of water mixed with abrasive media, we can cut intricate shapes and designs all while preserving the material’s structural integrity and without creating heat-affected zones (HAZ) on the base material.

Whether you need prototypes, one-off parts, or full production runs, our waterjet cutting capabilities ensure a high-quality finish and reliable performance for industries ranging from aerospace and automotive to architecture and custom fabrication.

Electrical Discharge Machining (EDM)

Our EDM machines can cut even the hardest materials with unmatched accuracy delivering perfection in every cut, from aerospace components to intricate moulds. We also provide precision slotting solutions, crafting keyways and specialized slots to meet the industry’s highest standards. The machine can craft intricate shapes with top-tier precision, ideal for fine mechanical parts and medical devices.