Special Purpose Machines

Our Special Purpose Machines (SPMs) are tailor-made automation systems designed to meet specific operational requirements that standard machinery cannot fulfil. Engineered for precision, reliability, and efficiency, our SPMs are developed in close collaboration with clients to solve unique challenges across manufacturing and processing environments. Whether it’s a semi-automated workstation or a fully automated line, we deliver machines that fit seamlessly into your operations.

Key Features:

Fully Customized Designs: Built to meet exact application needs, including assembly, inspection, testing, handling, and machining.

High Precision and Repeatability: Designed for consistent performance, even in high-volume production environments.

Advanced Controls and Automation: Integrated with PLCs, HMIs, sensors, robotic systems, and data logging systems.

Robust Construction: Engineered using durable materials and components to withstand continuous industrial use.

Turnkey Solutions: Includes concept develo

pment, design, fabrication, integration, and commissioning.

Benefits:

Improved Productivity: Automates repetitive or complex processes to reduce cycle time and increase output.

Reduced Labor Dependency: Minimizes manual intervention and ensures process reliability.

Consistent Quality: Enhances process consistency, reduces human error, and ensures product uniformity.

Lower Operational Costs: Optimizes resource usage, energy efficiency, and overall maintenance needs.

Scalability and Flexibility: Designed to adapt to e

volving production requirements and future upgrades.

Applications:

Our SPMs are trusted across a wide range of industries including automotive, electronics, medical devices, FMCG, packaging, plastics, and precision engineering.

Our SPM catalogue includes:

Linear TIG Welding Machine

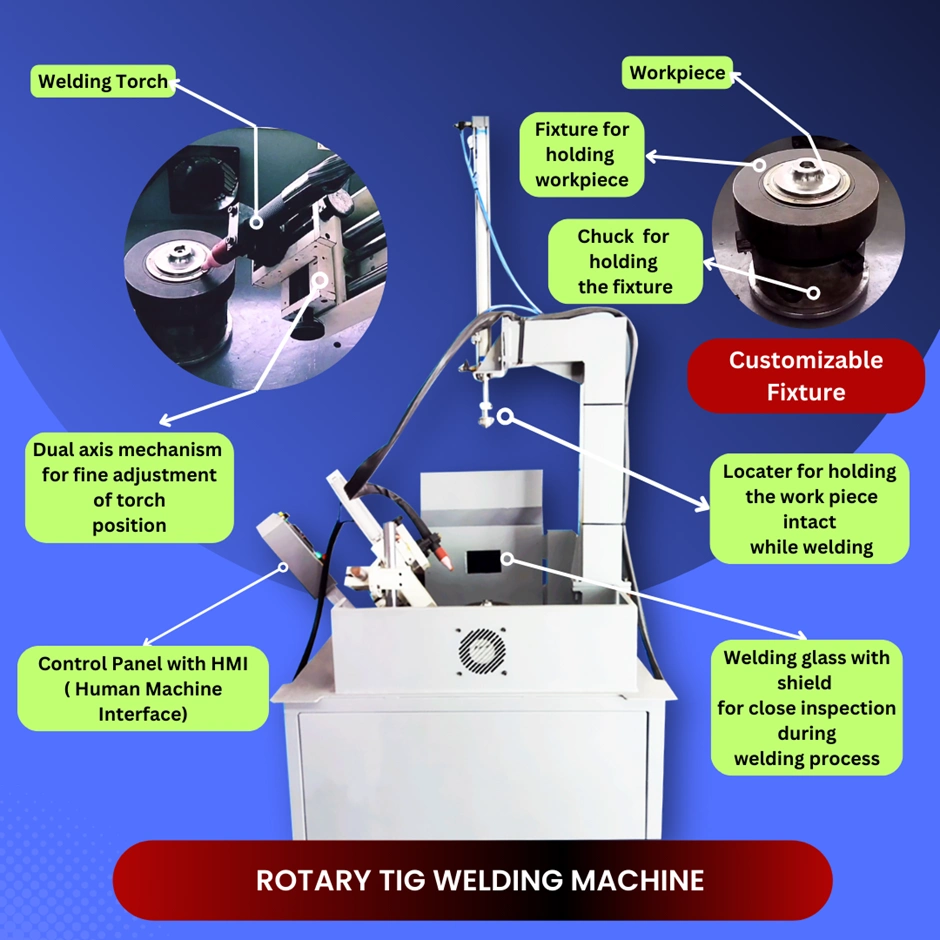

Rotary TIG Welding Machine